ABOUT BARRICADE BRACKET

ABOUT BARRICADE BRACKET

The importance of a safe construction site cannot be overemphasized. Even with great vigilance, there is still an ever-present danger and a greater likelihood for accidents – on every construction job site. That is the very reason and absolute need for the Barricade Bracket.

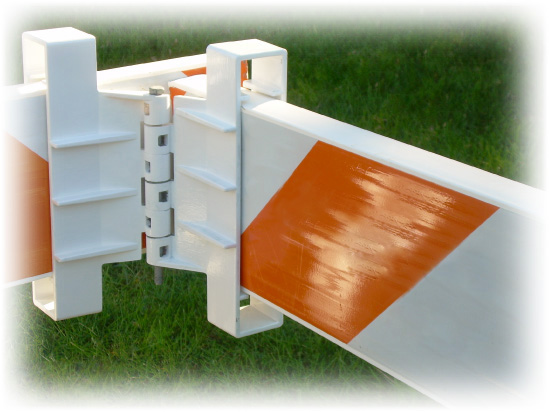

The patented Barricade Bracket has been designed to enhance the work zone.Barricade Bracket is the only one of its kind. Its unique durable, yet lightweight, design offers a greater measure of safety, allows your company to conform to all safety specifications and an overall cost savings.

Benefits

- Greater safety of job sites.

- Joins barricades with highly flexible angling (0 - 180) for nearly any configuration.

- Eliminates barricade gaps, preventing pedestrian shortcuts.

- OSHA compliant; allows your company to conform to MUTCD specifications.

- Substantial cost savings; up to 30%.

- Made with 100% recycled high-density polyethylene.

- Uneven terrain poses no obstacle for bracket.

- Bracket accommodates plastic, I-beam and wood barricade arms.

- Weatherproof and wind resistant construction ensures integrity of use in harsh elements.

- Compact design allows for easy transportation and space-saving storage.

- Links numerous arms forming endless straightaway.

- Forms an enclosed, impenetrable work zone.

- Proudly Made in the U.S.A.

How It Works

The Barricade Bracket is designed to work in conjunction with A-frame barricades to provide a more secure enclosed work zone. It will eliminate the need for two legs per barricade. By replacing one leg with two Barricade Brackets, you will provide a safer, sturdier and protective work zone. Simply by eliminating legs from a typical work zone you will automatically decrease the potential for a tripping hazard.

If using two arms (one top and one bottom) you will need two Barricade Brackets for each leg replaced. If your work site only uses one top arm, you will only need one Barricade Bracket for each leg replaced.